Overview:

Silk screen printed silicone keyboards are high-performance components widely utilized in various industries, thanks to their exceptional durability and reliable tactile feedback. Manufactured through the silicone compression molding process, these keyboards feature vibrant, long-lasting graphics and labels, enhancing both functionality and aesthetics. Custom logo printing options allow for tailored branding, making them suitable for diverse applications. The inherent flexibility of silicone, combined with the precision of silk screen printing, ensures an outstanding user experience and optimal performance in demanding environments. Whether for home appliances or industrial machinery, these keyboards deliver remarkable durability, chemical resistance, and adaptability to custom design specifications, making them an ideal choice for a wide range of uses.

Details:

| Specification | Details |

| Place of Origin | Fujian, China |

| Brand Name | OEM |

| Application | Home Appliance |

| Keypad Button Material | Silicone |

| Material | Silicone |

| Color | RAL Color / Pantone |

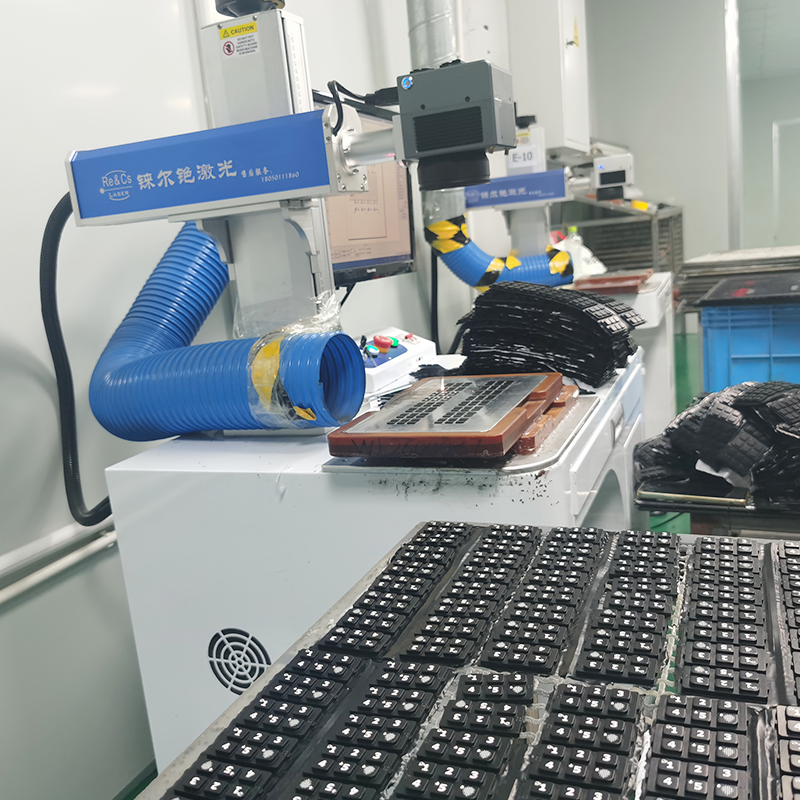

| Printing | Screen Printing / Laser Etching |

| Mold | Compression Mold |

| Conduction | Carbon Pills / Ink / Metal Domes / Metal Pills |

| Size | Customized Size |

| Product Name | Silicone Button |

| Logo | Customized Logo |

| Usage | Electric Appliance |

| Certification | ISO 9001:2015 |

The Production Process of Silkscreen Silicone Keyboards:

- Material Selection: High-quality silicone rubber is chosen for its durability and flexibility, tailored to application needs.

- Mold Design: Custom molds are engineered for precise dimensions and features of the silicone keyboards.

- Silicone Compression Molding: Silicone material is placed in the mold and subjected to heat and pressure, forming the keyboard base.

- Silkscreen Printing: Vibrant graphics and logos are applied using silkscreen printing for lasting quality.

- Quality Inspection: Finished keyboards undergo thorough quality checks to ensure durability and functionality.

- Final Assembly: Additional components, like conductive elements, are integrated for complete functionality.

- Packaging and Shipping: The keyboards are packaged securely and prepared for shipment to ensure timely delivery.

Surface Protection Options for Silicone Keyboards:

- Matte Smooth Coating (Oil Coating): Provides a soft, tactile finish that enhances grip while reducing fingerprints and smudges.

- PU Coating: A polyurethane layer that offers superior durability and resistance to wear, chemicals, and UV exposure.

- Epoxy Coating: Delivers a hard, protective finish that enhances surface integrity and provides excellent abrasion resistance.

- Silicone Key with Plastic Button Cap: Incorporates a plastic cap for improved durability and a tactile response, ideal for various applications.

- Silicone Key with Metal Button Cap: Features a metal cap for added robustness and a premium feel, suitable for high-use environments.

Why Choose Us?

- Finished Product Inspection:

– Each product undergoes a thorough inspection to ensure compliance with stringent quality standards and customer specifications. This diligent process guarantees that you receive reliable and high-quality products.

- Sample-Based Customization:

– We offer customization based on submitted samples, enabling us to accurately replicate and enhance existing designs. This ensures the final product aligns seamlessly with your expectations.

- Comprehensive Customization:

– Our full customization services allow us to tailor every aspect of the mold to your precise requirements. From design to production, we focus on every detail to meet your unique needs.

- OEM Services:

– Our OEM services enable the creation of entirely new designs based on your concepts. We manage the entire process, from initial design through to final production, delivering innovative solutions that differentiate your products in the market.