Overview:

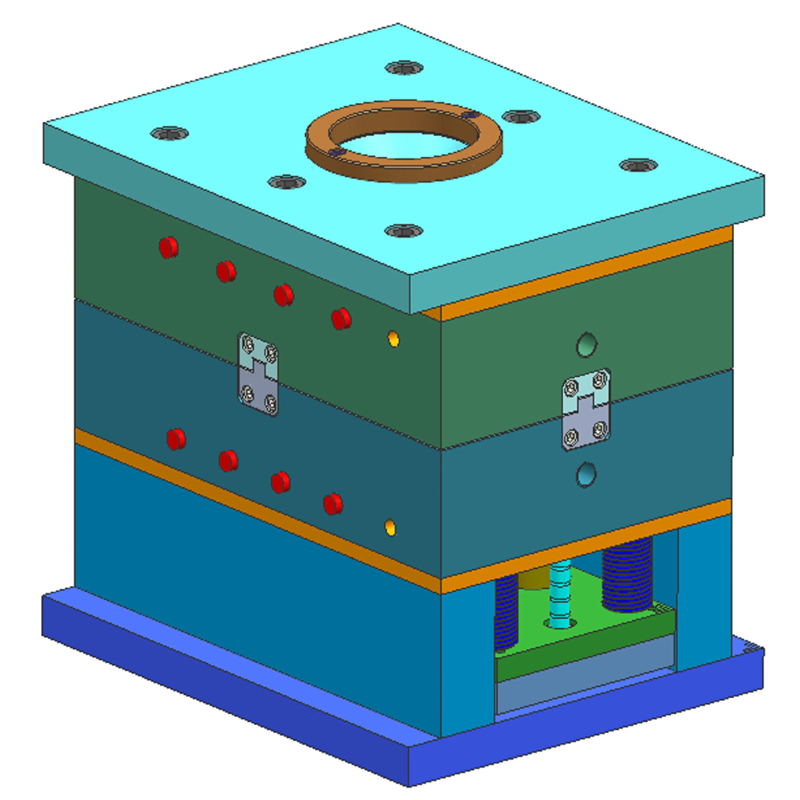

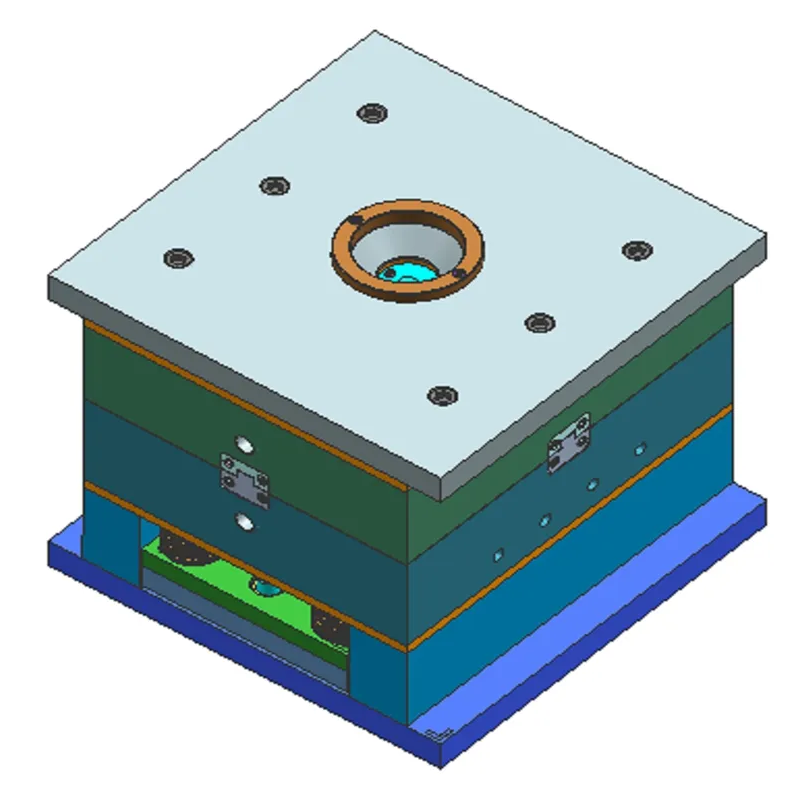

Our factory offers advanced LSR overmolded plastic keyboard mold tooling for the electronics industry, combining the durability of plastic with the flexibility of Liquid Silicone Rubber. Our custom and OEM solutions provide superior tactile feedback, wear resistance, and ergonomic design for a variety of electronic devices. Using state-of-the-art EDM and CNC machining processes, we ensure precision and quality in every mold, delivering high-performance components for your business needs. Contact us for more information on our LSR overmolding services.

Features:

| Parameter | Details |

| Mold Type | Overmolding Mold |

| Mold Base Standards | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Runner System | Cold Runner / Hot Runner |

| Mold Gate Options | Slide Gate, Sub Gate, Pin-point Gate |

| Cavity | Single or Multi-Cavity |

| Design Software Supported | UG, PROE, CAD, SOLIDWORKS |

| Molding Equipment Used | CNC, Wire Cutting, Milling Machine, EDM |

| Compatible Raw Materials | ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc. |

| Packaging Method | Wooden pallet or carton |

| OEM Services | Available—please provide 2D/3D files or samples |

| Lead Time | Approximately 30 days |

Production Process of Keyboard Mold:

The production of Keyboard mold tooling involves several key stages to ensure precision and functionality:

-

Design and Engineering

Engineers create detailed 3D CAD models, considering material selection, mold functionality, and manufacturability to ensure optimal performance.

-

Material Selection

High-quality materials like steel or aluminum are chosen for durability and compatibility with molding processes.

-

Tooling Fabrication

CNC machining and EDM are used to fabricate mold cavities and components with high precision, ensuring intricate details for the Keyboard.

-

Mold Assembly and Testing

The mold is assembled and tested for proper alignment and functionality, with prototype parts made for verification.

-

Molding Process

The mold is used for injection or compression molding to create the silicone or plastic Keyboards.

-

Post-Molding Processes

Surface finishing, trimming, and quality checks are performed to ensure the Keyboards meet functional and aesthetic standards.

-

Final Inspection and Quality Control

The Keyboards undergo dimensional and functionality tests to ensure they meet required specifications before mass production.

Our Strength:

-

Comprehensive Final Product Inspection

– Each finished product undergoes a thorough inspection process to ensure it meets all quality standards and customer specifications. This rigorous approach guarantees the highest level of quality, performance, and reliability in every product.

-

Sample-Based Customization

– We offer customization based on submitted samples, enabling us to replicate and refine existing designs. This ensures the final product meets your exact specifications while enhancing overall design quality.

-

Fully Tailored Customization

– Our full customization services allow for complete tailoring of the mold to your specific requirements. From initial design through to production, we ensure every detail is crafted to meet your exact needs and specifications.

-

OEM Services

– Our OEM services support the creation of entirely new designs based on your ideas. We manage the entire process, from concept development to final production, providing innovative solutions that distinguish your products in the marketplace.

Our Factory:

We operate a comprehensive array of state-of-the-art plants and equipment to ensure the highest standards of production quality. Our mold-making facilities are equipped with advanced technologies, including CNC machines, Mirror EDM, EDM, Slow-speed Wire Cut (WC), and various auxiliary equipment to support precision manufacturing.

In addition, our production capabilities feature 15 rubber compression molding machines and 2 LSR injection molding machines, enabling efficient and flexible production processes. To uphold strict quality standards, we utilize advanced tools such as 3D projectors, sealing testers, elasticity measurement devices, durometers, and a skilled quality control team.

Our mechanical equipment suite further includes an AutoDryer line, automatic screen printing machines, 3D measuring instruments, high-speed automatic doming machines, die-cutting machines, automatic die-cutting systems, CNC machines, and more. This combination of cutting-edge automated production lines, precision equipment, and robust quality control processes ensures we consistently deliver products of the highest quality.