Overview:

Custom plastic keyboard keycaps made with high-quality plastic injection molding for durability and flexibility. Ideal for electronics, medical devices, and industrial applications, these keycaps provide superior tactile feedback and resistance to wear. OEM customization available to meet your unique design requirements.

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Plastic |

| Size | Custom size available |

| Color | Pantone card number |

| MOQ | Based on your requirements |

| Shape | Custom shape available |

| Hardness | 20-80 Shore A |

| Usage | Suitable for all industries |

| Features | Anti-slip, strong adhesive sticker |

Production Process:

-

Design and Prototyping

The process starts with creating a detailed design using CAD software. A prototype is made to test fit and functionality before approval.

-

Tooling and Mold Creation

Once the design is finalized, a mold is created using high-quality steel or aluminum. CNC machining is used to ensure precise dimensions.

-

Injection Molding

Plastic resin, like ABS or PBT, is injected into the mold under high pressure. The material cools and hardens, forming the keycap shape.

-

Post-Processing

After molding, keycaps undergo finishing processes like trimming excess material, smoothing edges, and adding custom finishes (e.g., painting or laser etching).

-

Quality Control and Inspection

Keycaps are inspected for defects in color, size, and shape. Any keycaps that do not meet standards are rejected.

-

Customization and Branding

Custom logos, text, or other elements are added through methods like UV printing or laser engraving.

-

Packaging and Shipping

The finished keycaps are carefully packaged and shipped to customers.

key Advantages of Keycaps:

- Durability: Made for long-lasting performance, these keycaps resist wear and maintain their functionality over time.

- Customization: OEM options allow for tailored shapes, sizes, and colors to meet specific design and branding needs.

- Tactile Feedback: Provides excellent user comfort and responsiveness, enhancing the typing experience.

- Cost-Effectiveness: Efficient plastic injection molding ensures high-quality production at an economical cost.

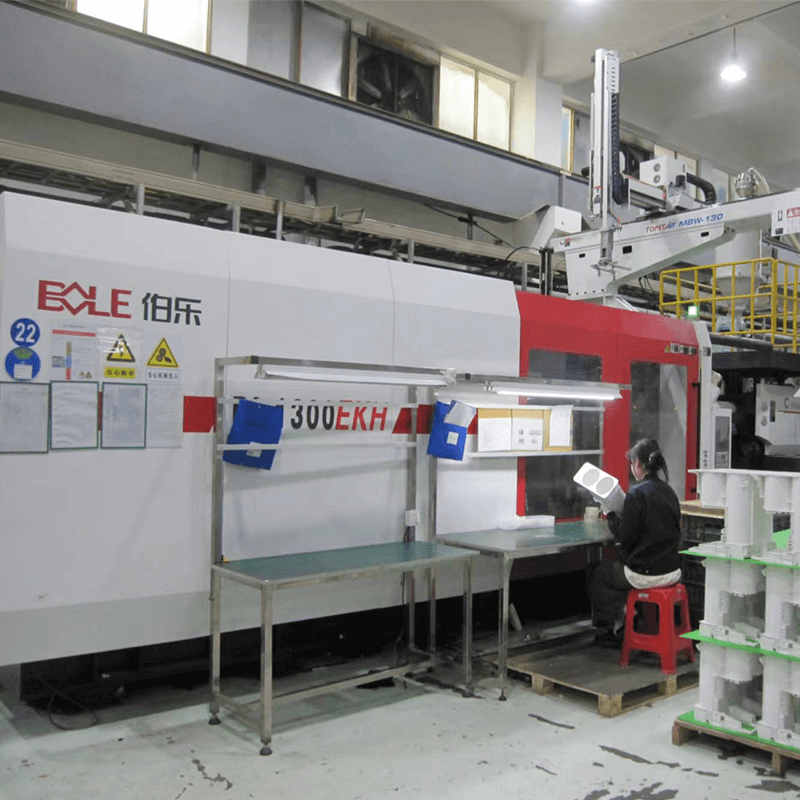

Our Factory:

We operate a comprehensive suite of advanced machinery to ensure top-tier production quality. Our mold-making facilities include CNC machines, Mirror EDM, EDM, and Slow-speed Wire Cut (WC), supported by essential auxiliary tools.

Our production lines feature 15 rubber compression molding machines and 2 Liquid Silicone Rubber (LSR) injection machines, complemented by precision testing equipment such as 3D projectors, sealing testers, durometers, and a dedicated QC team.

Additionally, we utilize AutoDryer Lines, automatic screen printing machines, 3D measuring instruments, high-speed doming machines, and CNC machining centers. This combination of cutting-edge equipment and rigorous quality control ensures consistent, high-quality results.