Overview:

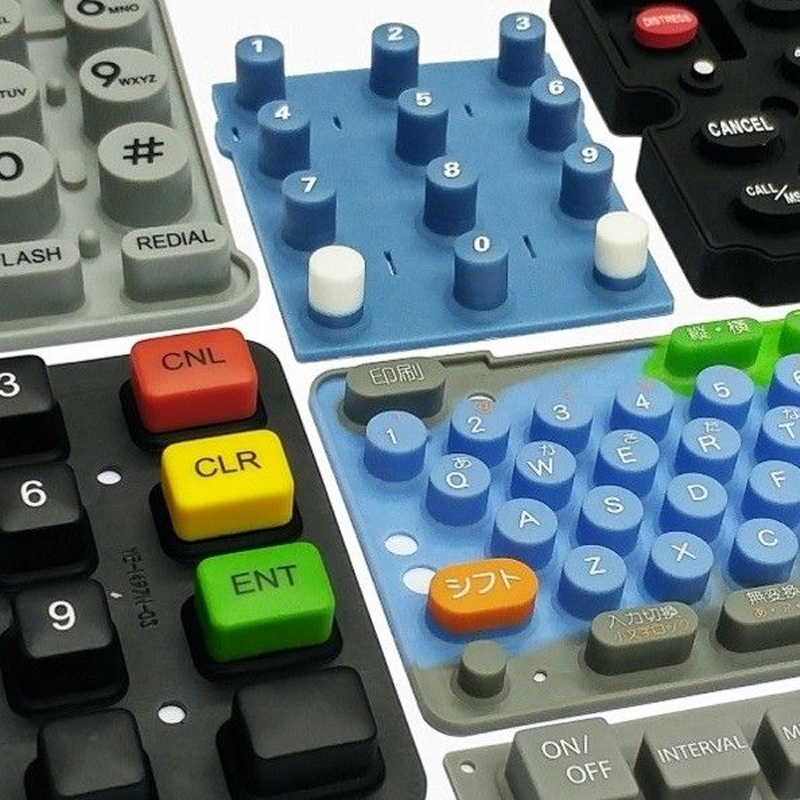

The Color-Treated Silicone Rubber Keypad stands out as a versatile and indispensable component, due to its aesthetic appeal and versatility in manufacturing processes.

The Color-Treated Silicone Rubber Keypad stands out as a versatile and indispensable component, due to its aesthetic appeal and versatility in manufacturing processes.

The spray technology commonly used for The Color-Treated Silicone Rubber Keypad is typically pad printing or screen printing. These methods allow for precise application of ink onto the silicone surface, ensuring vibrant colors and durability. Pad printing involves transferring ink from a silicone pad onto the keypad’s surface, while screen printing uses a stencil (screen) to apply ink directly onto the silicone. We employ advanced precision technologies for both pad printing and screen printing, supported by robust factory designs that ensure consistently high product quality over the long term.

Features Include:

| Detection Method | Correlation Type |

| Materials | Silicone Rubber |

| Environmental Friendly | SGS, RoHS |

| Surface Coating | PU Coating, Matte Smooth Coating, Epoxy Coating |

| Place of Origin | Xiamen, China |

| Color | Any color is available (as customer request) |

| Logo | Customized |

| Production Capacity | 50,000 PCS/Week |

| Contact Resistance | 10-200 Ohm |

| Legend | Silk Screen, Laser Etching |

| Conductive Way | Conductive Printing, Carbon Pills, Metal Dome |

| Transport Package | Poly Bag, Carton Boxes |

Color-Treated Silicone Rubber Keypad Features and Benefits:

- Durability: Resistant to wear, tear, and environmental factors, making it ideal for long-term use.

- Flexibility: Maintains structural integrity while offering tactile flexibility, enhancing user experience.

- Tactile Feedback: Responsive buttons that provide satisfying tactile feedback, improving usability and accuracy.

- Customizable Colors: Available in a wide array of colors including black, gray, blue, red, and more.

Color Silicone Rubber Applications:

- Electronics: Control panels, remote controls, and consumer electronics.

- Automotive: Dashboard controls, keyless entry systems, and infotainment interfaces.

- Medical Devices: Diagnostic equipment, patient monitoring systems, and surgical instruments.

- Industrial Equipment: Machinery controls, factory automation, and rugged environments.

Three Color Silicone Buttons Processing Methods:

- One-time Molded Multi-color Buttons

- Overmolded Rubber Multi-color Keypad

- Colore Coating Silicone Buttons

Our Service About The Packing And Shipping:

Packaging:

- Protection: Products are securely packed to prevent damage during transportation. This includes using appropriate padding, cushioning materials, and sturdy containers.

- Customization: Packaging may be customized to meet specific regulatory requirements, such as labeling for international shipping, or tailored to fit product dimensions efficiently.

- Branding: We can incorporate your brand elements into the packaging to enhance marketing and increase brand awareness.

- Documentation: We ensure all necessary documentation, such as packing lists, invoices, and certificates of origin, are included and correctly labeled on packages.

Shipping:

- Logistics Planning: Coordinating logistics, including selecting shipping methods (sea freight, air freight, or land transport), based on factors like cost, transit time, and product characteristics.

- Compliance: Adhering to international shipping regulations and customs requirements, including tariffs, duties, and import/export restrictions.

- Tracking and Traceability: Providing tracking information to monitor shipment progress and ensure transparency throughout the shipping process.

- Customer Support: Offering support services to handle inquiries, address issues related to shipping delays, customs clearance, or other logistical challenges.

Our Other Services:

- Full Project Management

- Supply Chain Integration

- Packaging and Logistics

- After-Sales Support