Overview:

Carbon pill buttons represent a specialized type of conductive silicone keyboard, renowned for their durability compared to keyboard that utilize conductive ink printing. These carbon pill switches are constructed from silicone rubber that is infused with graphite, enhancing their conductive properties. When a user presses the silicone rubber buttons, the carbon pills make contact with the circuit board, completing the electrical circuit and facilitating the necessary current flow.

Features:

| Product Specifications | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Silicone |

| Shape | Custom shape |

| Color | Custom color |

| Coating | PU / Soft matt / Epoxy, etc. |

| Secondary Processing | Soft matt coating, Epoxy coating, PU coating, laser etching, etc. |

| Additional Service | Metal dome, PCB and flexible FPC/PET assembly |

| Service | OEM Service |

| Logo | Custom |

| Certificates | ISO |

Advantages of Carbon Pill Silicone Keypbaords:

-

Superior Durability

Carbon pill switch buttons are more durable than conductive ink keypads, maintaining stable electrical resistance over time, unlike conductive ink options that can degrade with use.

-

Cost-Effective

Compared to expensive metal dome or gold pill keypads, carbon pill silicone keypads offer a more affordable solution while meeting necessary resistance requirements, making them an economical choice for manufacturers.

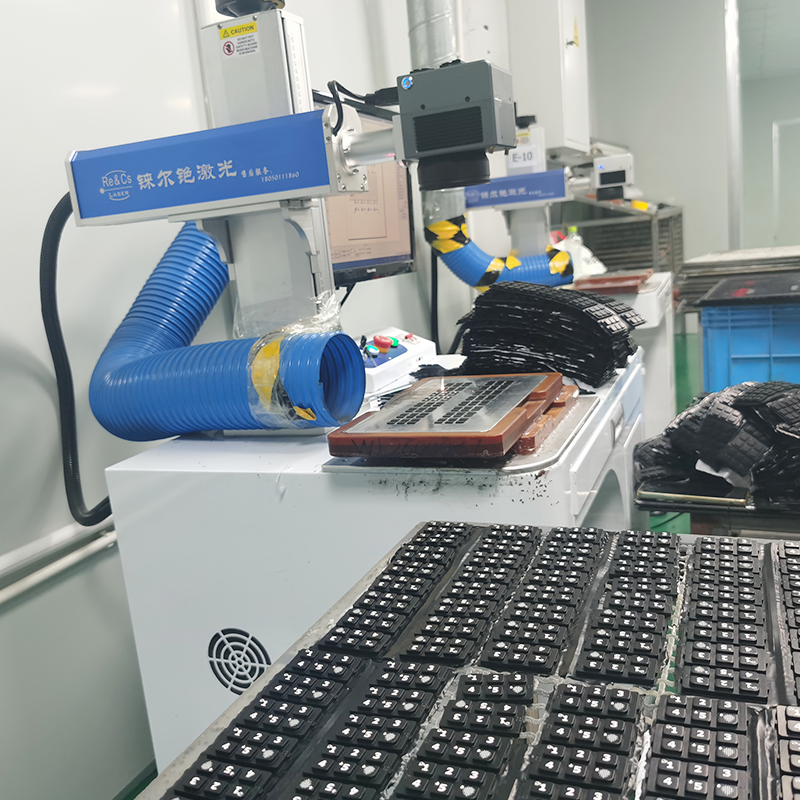

Manufacturing Process of Carbon Pill Silicone Buttons:

-

Preparation of Carbon Pills

Carbon pills are prepared for integration into the keypad during the molding process.

-

Positioning in Mold

Using a positioning tool, the carbon pills are accurately placed into the mold cavities before compression molding begins.

The silicone material is introduced into the mold, where it surrounds the positioned carbon pills.

![]()

-

Vulcanization

The mold is subjected to vulcanization, allowing the carbon pills to bond with the silicone material.

-

Temperature and Time Control

Careful control of vulcanization time and mold temperature is essential. Low temperatures may cause the carbon pills to dislodge, while high temperatures can lead to the melting of the pills into the silicone matrix.

-

Final Product

Once the vulcanization process is complete, the resulting carbon pill silicone buttons are ready for quality inspection and further processing.

Surface Options for Carbon Pill Buttons:

-

Matte Finish

A matte finish provides a non-reflective surface that enhances grip and visibility, making it ideal for applications where glare reduction is essential.

-

Glossy Finish

A glossy finish offers a smooth and reflective surface that enhances the aesthetic appeal of the buttons, often suited for modern and sleek designs.

-

Epoxy Coating

An epoxy coating provides a durable, protective layer that enhances the lifespan of the buttons. This option can improve resistance to wear and environmental factors, making it suitable for demanding applications.

-

Laser Etching

Laser etching allows for precise customization of button designs and labels, creating clear and durable markings. This technique is particularly beneficial for adding logos or specific functionality indications without compromising the surface integrity.

Quality Control:

To guarantee the highest quality of our silicone keypads, we employ a comprehensive multi-channel inspection process and facilitate third-party evaluations. Additionally, we accept returns of any non-conforming products without requiring a reason. Below are the essential steps in our quality assurance process:

Silicone Keypad Alcohol Abrasion Test

This test involves a rigorous assessment of the silicone buttons’ surface by continuously rubbing it to verify that the text and coating remain intact, without any wear or abrasion over time.

Silicone Keyboard Material Tensile Force Test

We conduct tests on the tear strength and tensile force of the silicone material to ensure that the keypads exhibit durability and resistance to tearing, meeting our high standards for product longevity.