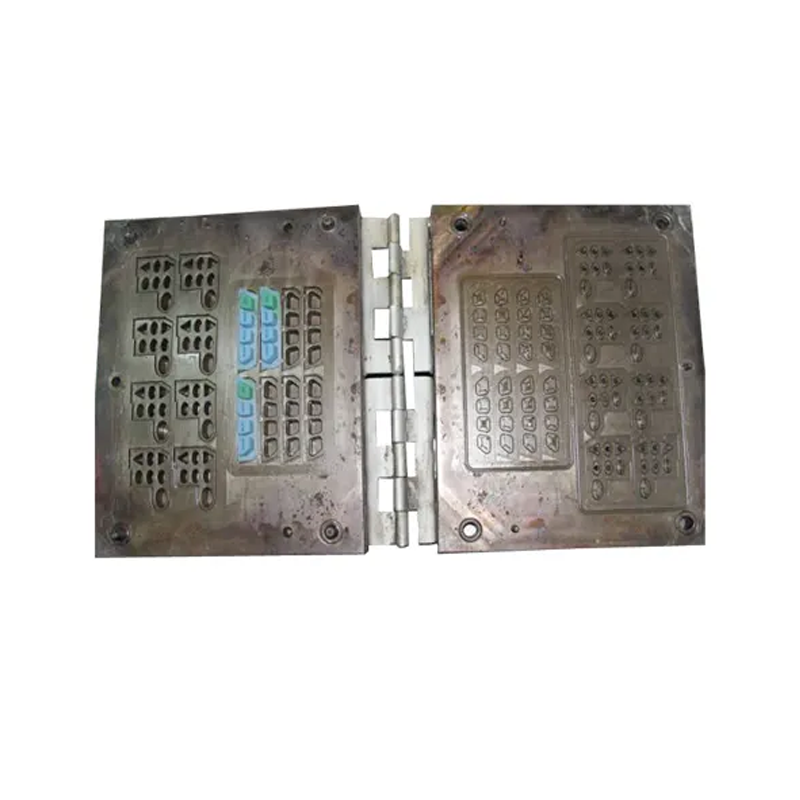

Overview:

Silicone keyboard mold refers to the specialized molds used for producing silicone keypads and keyboards, typically made from high-grade steel or aluminum materials. The manufacturing process involves advanced machinery, including CNC machining centers, and precision cutting tools, ensuring exceptional accuracy and efficiency. Surface treatments such as polishing or coating may be applied to enhance durability and functionality. Our state-of-the-art equipment allows us to create a wide variety of molds tailored to meet specific customer requirements. Whether based on client designs or innovative concepts, we are committed to delivering high-quality silicone keyboard mold that aligns with your vision and industry standards.

Characteristics:

| Specification | Details |

| Mold Type | Silicone Compression Mold |

| Mold Material Options | P20, 718, 738, NAK80, S136 |

| Mold Base Standards | HASCO, DME, MISUMI, JIS, LKM |

| Mold Runner System | Cold Runner / Hot Runner |

| Mold Gate Options | Slide Gate, Sub Gate, Pin-point Gate |

| Cavity | Single or Multi-Cavity |

| Design Software Supported | UG, PROE, CAD, SOLIDWORKS |

| Molding Equipment Used | CNC, Wire Cutting, Milling Machine, EDM |

| Compatible Raw Materials | ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS |

| Packaging Method | Wooden pallet or carton |

| OEM Services | Available—please provide 2D/3D files or samples |

| Lead Time | Approximately 30 days |

Advantages of Our Mold:

-

Exceptional Quality:

– Our molds are produced using premium-grade materials and cutting-edge manufacturing techniques, ensuring outstanding durability, precision, and longevity. Each mold undergoes thorough quality assurance inspections to comply with rigorous industry standards.

-

Tailored Customization:

– We provide highly customizable mold designs specifically tailored to meet the individual requirements of our clients. Our team collaborates closely with customers to develop molds that align seamlessly with their distinct production needs and specifications.

-

Cutting-Edge Technology:

– Leveraging the latest advancements in CNC machining, laser cutting, and precision engineering, we craft our molds with unmatched accuracy. Our state-of-the-art technology guarantees consistent, high-quality results while minimizing production downtime.

-

Rapid Prototyping Solutions:

– We offer expedited turnaround times for prototypes, enabling clients to swiftly test and validate their designs. This accelerates the product development cycle, facilitating faster market entry.

Surface Treatment Options:

– Polished Finish:

– Achieves a high-gloss surface, enhancing aesthetic appeal and minimizing friction.

– Matte Finish:

– Provides a non-reflective surface, ideal for applications requiring a subdued appearance and improved grip.

– VDI (Verein Deutscher Ingenieure) Finish:

– A standardized surface finish that delivers precise texture and uniformity, commonly used for high-quality molded parts.

– SPI (Society of the Plastics Industry) Finish:

– Ensures consistency in surface texture and quality, aligning with industry standards for various mold applications.

– Ball Burnishing:

– A technique that enhances surface smoothness and finish through the use of ball-shaped tools, resulting in improved wear resistance and aesthetic quality.

Factory Show:

We maintain a diverse array of advanced machinery and facilities to guarantee superior production quality. Our mold-making operations are outfitted with cutting-edge equipment, including CNC machines, Mirror EDM, conventional EDM, slow-speed Wire Cut (WC), and precision milling machines. Additionally, we utilize laser cutting machines, 3D printers for rapid prototyping, and advanced surface treatment systems, all of which work in concert to enhance the accuracy and efficiency of our mold production processes.