Hello everyone! Sunny here from Rockeypad, your trusted partner in high-quality keyboard production. At Rockeypad, we know that molds are not just tools—they are the cornerstone of every keyboard we produce together. Their precision, reliability, and longevity directly influence the quality of your products. This is why we dedicate ourselves to providing top-notch maintenance and care for every mold entrusted to us. With injection machines applying up to 35 tons of pressure per cycle, maintaining molds is critical to reducing wear and tear while ensuring long-term performance.

Today, let’s explore the three essential pillars of mold maintenance: cleaning, repair, and storage. Each is a vital step in preserving the durability and functionality of your keyboard molds, helping to deliver consistent, high-quality results for years to come.

Thorough and Tailored Mold Cleaning

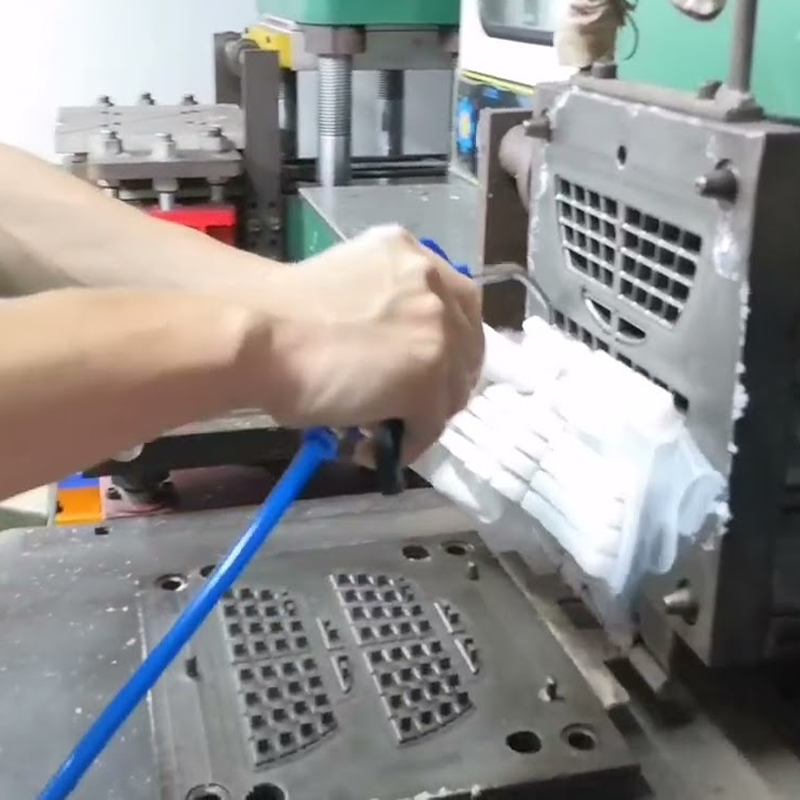

Over time, repeated usage leads to the buildup of dirt, grime, and residue on mold surfaces. This accumulation, if neglected, can compromise the mold’s precision and, consequently, the quality of the keyboards produced. At Rockeypad, we address this challenge with a detailed and thorough cleaning regimen tailored to each mold’s unique characteristics.

Every mold is different. Some feature intricate designs that require specialized tools to clean hard-to-reach crevices, while others have delicate surfaces that demand extra care. Our skilled technicians bring patience, expertise, and the appropriate tools to every cleaning session, ensuring each mold is handled with care and precision.

For molds with complex structures or intricate details, disassembly is often necessary to access hidden areas. This meticulous process ensures no residue is left behind, whether it’s polishing a high-gloss surface or removing stubborn buildup from tight grooves. By restoring molds to their original condition, we not only improve their immediate performance but also extend their lifespan significantly.

Proactive Repair and Maintenance

Even with the best care, mold wear and tear is inevitable. Injection cycles exert immense pressure, and over time, this can lead to minor imperfections such as dents or scratches. At Rockeypad, we take a proactive approach to repair and maintenance to address these issues before they affect the quality of your keyboard components.

Our process begins with thorough inspections after every production run. If any damage is detected, our experienced in-house engineers step in to restore the mold’s structural integrity and functionality. Their expertise ensures that repairs are carried out with precision, keeping molds in peak condition for consistent performance.

Certain molds, such as those with polished or mirrored surfaces, demand extra attention. These molds are particularly susceptible to scratches, which can impact the final product’s appearance. To maintain their quality, these molds undergo regular polishing as part of a customized maintenance schedule. For molds prone to recurring damage, we create individualized care plans to address their unique needs.

We also implement protective measures during handling and storage. Molds are covered with protective mats when not in use and cleaned with non-abrasive materials like cotton and wooden tools. These small but crucial steps prevent unnecessary damage and maintain the high standards our customers expect.

Secure and Systematic Mold Storage

Proper storage is a critical yet often overlooked aspect of mold care. At Rockeypad, we ensure that your molds are stored under optimal conditions to preserve their quality and readiness for future use.

Once a production order is complete, every mold undergoes a detailed inspection. Any necessary cleaning or repairs are performed before the mold is tagged and prepared for storage. Molds are stored in a closed position to protect their surfaces from dust, dirt, and accidental damage. This secure environment keeps them in top condition while they await their next production cycle.

When a new order is placed, the mold is retrieved from storage, given a quick inspection to confirm its readiness, and carefully prepared for use. This streamlined process minimizes downtime and ensures that your molds consistently produce high-quality keyboard components.

Our storage solutions are more than just practical—they reflect the trust you place in us to safeguard your molds as valuable assets.

Why Rockeypad Stands Out

At Rockeypad, our commitment to excellence goes beyond manufacturing keyboard components. We are dedicated to providing comprehensive mold care solutions that ensure the longevity, precision, and performance of your molds.

Our team of highly skilled engineers continuously refines our cleaning, repair, and storage processes to uphold the highest standards. We also offer personalized maintenance plans tailored to the unique needs of your molds, ensuring that they receive the care and attention they deserve.

Partnering with Rockeypad means choosing a company that prioritizes your success. From meticulous mold maintenance to seamless production processes, we are here to support you every step of the way.

If you’re ready to elevate the care and performance of your keyboard molds, we’d love to hear from you. Contact Rockeypad today to discover how our expertise and dedication can make a difference for your business. Together, we can achieve unparalleled quality and consistency in every keyboard you produce!